Products » Multi-Axis Systems » EZ-GS0760 Dynamic Wafer Stage

Dynamic Wafer Stage

EZ-GS0760 | Key Features

- X/Y Stage with Focus Axis (Z)

- Impulse Decoupled X- & Y-Axis

- High-Precision Positioning < ± 100 nm

- Position Stability < ± 5 nm

- Repeatability < ± 40 nm @ 3 σ

- Y-Axis Acceleration up to 8 g

- Integrated XY SIOS Differential Laser Interferometer

- Quick-swap Lift-Pin Mechanism

Downloads

Product description

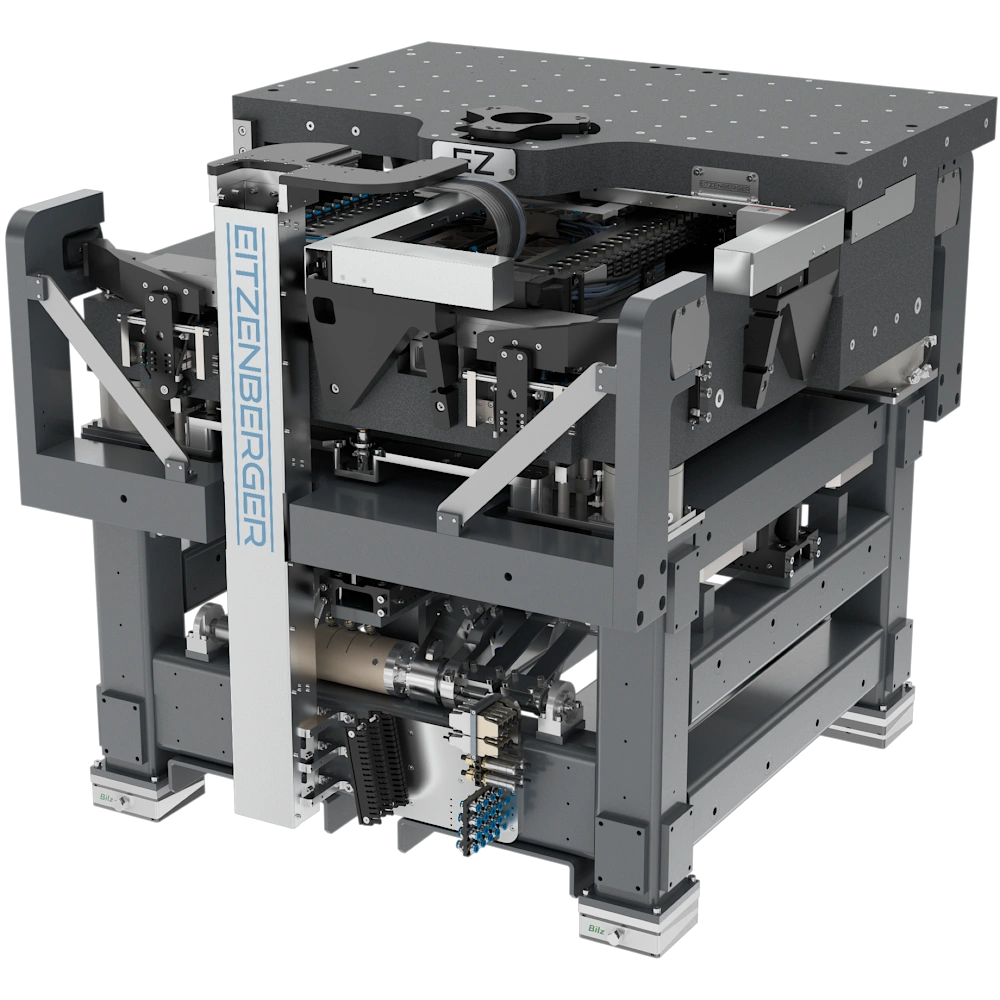

The EZ-GS0760 wafer stage has been developed for high-dynamic processes, such as laser fuse cutting. It offers excellent repeatability, optimal accuracy, and exceptional dynamic performance.

Built-in features:

- Mechanical impulse decoupling in both the X- and Y-axes for enhanced dynamic and positional stability.

- The unique design with a common reaction mass for both axes keeps reaction forces independent of the measuring frame and minimizes mass.

- A high-resolution SIOS differential laser interferometer ensures virtually Abbe-error-free performance, minimizing measurement errors at the point of interest, even at maximum dynamics.

- Outstanding Y-axis acceleration up to 8 g; water cooling allows travel profiles with up to 2 g continuous acceleration.

- The Y-axis natural frequency, including wafer chuck, exceeds 500 Hz.

- The compact height of just 87 mm provides a low center of gravity and enables high dynamics.

- Large top plate (granite) to accommodate customer applications.

Applications: Fuse cutting, high-precision positioning, scanning, and on-the-fly laser processes

Specifications

Type | Unit | Value |

|---|---|---|

| Positioning Range X/Y | ||

| Stroke Z | ||

| Max. Payload X/Y (for dynamic applications) | ||

| Max. Payload Z (for dynamic applications) | ||

| Accuracy X/Y (3σ) | ||

| Accuracy Z | ||

| Repeatability X/Y (3σ, bidirectional) | ||

| Repeatability Z (bidirectional) | ||

| Horizontal Straightness X/Y | ||

| Vertical Straightness X/Y | ||

| Pitch X/Y | ||

| Roll, Yaw X/Y | ||

| Pitch, Yaw Z | ||

| Max. Speed (X/Y) with 10 kg payload | ||

| Max. Acceleration unloaded (X/Y) | ||

Mechanical Data | ||

| Both Axes (X/Y) | ||

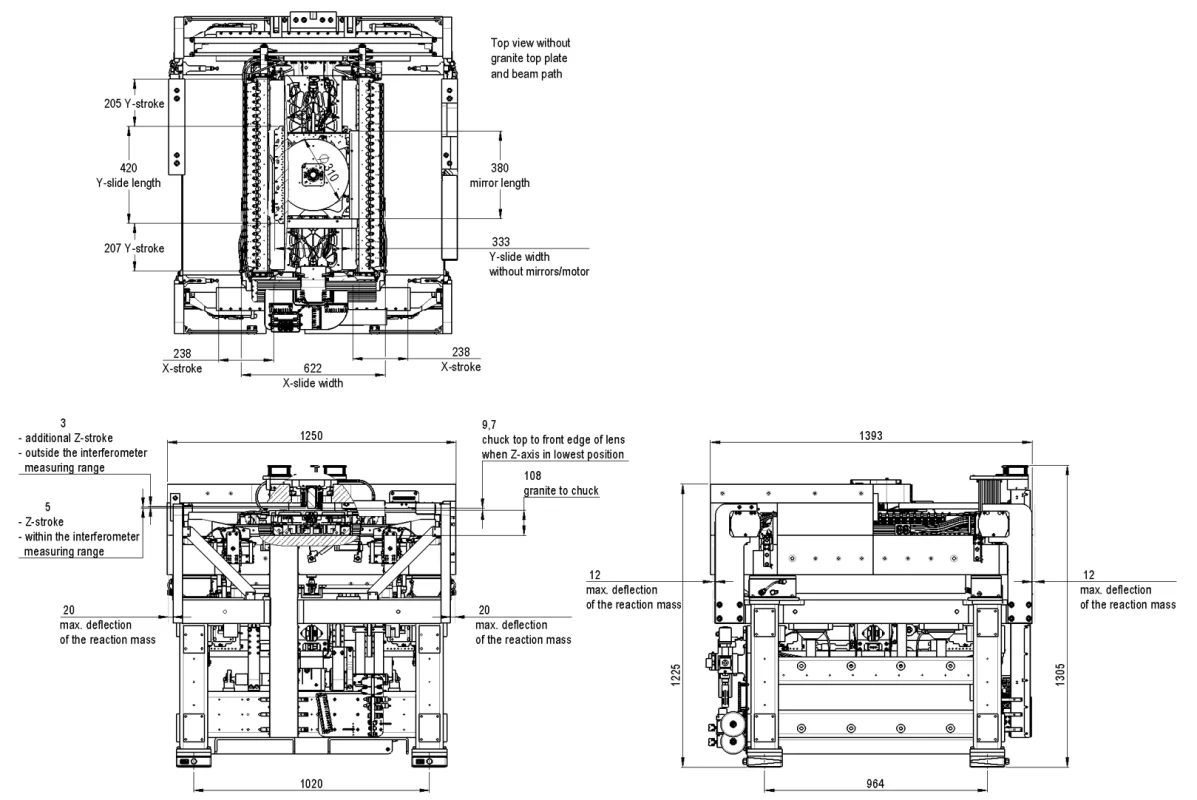

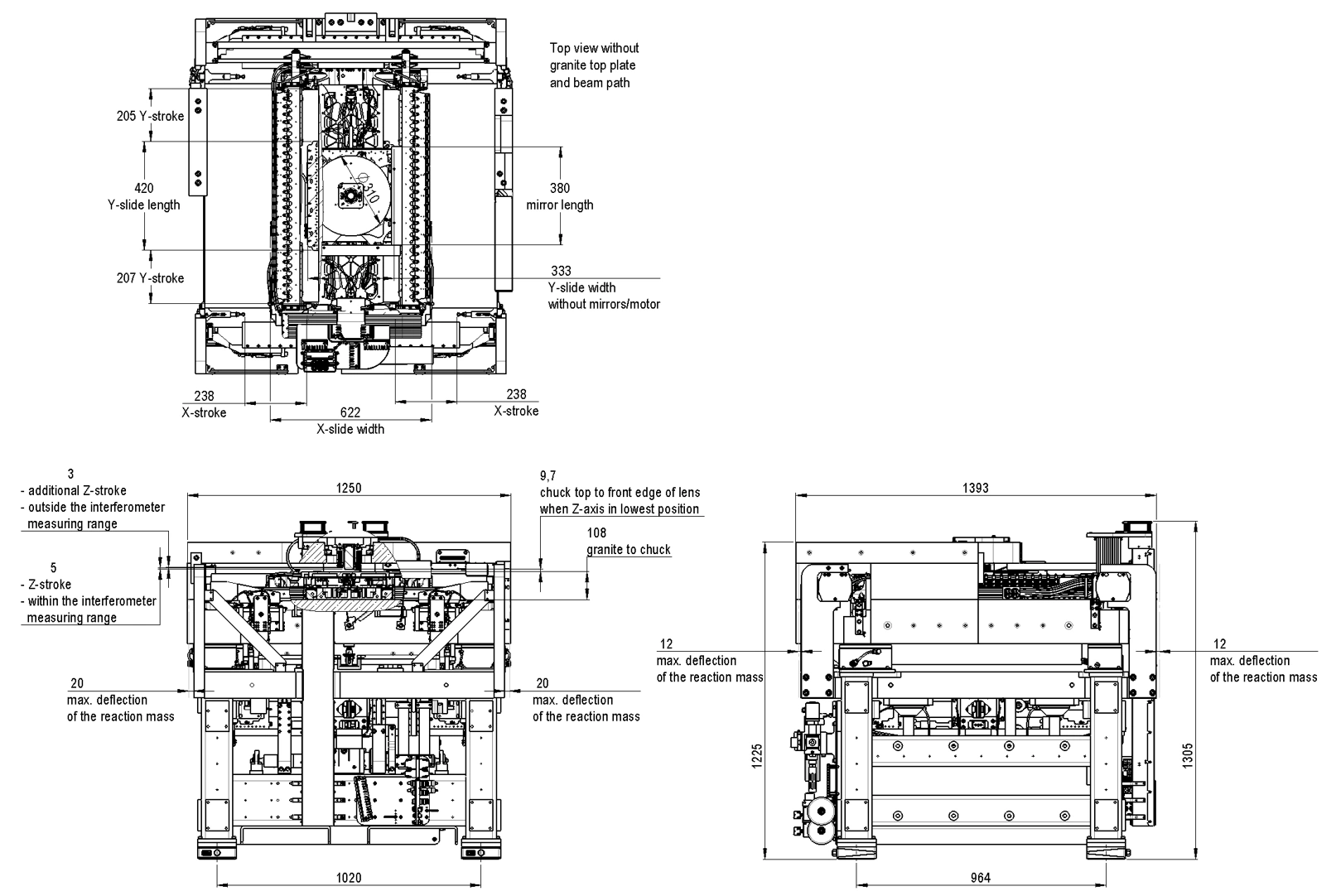

| Dimension (w x l x h) | ||

| Reaction Mass | ||

| Total Mass | ||

Encoder | ||

| Type | ||

| Signal | ||

Interferometer | ||

| Type | ||

| Resolution | ||

| Wave Length / Class | ||

Drive | ||

| Type X/Y (2 drives for X-axis) | ||

| Intermediate Circuit Voltage | ||

| Constant Force X / Y | ||

| Peak Force X / Y | ||

Interfaces and Environment | ||

| Supply Pressure | ||

| Vacuum Pressure | ||

| Air Consumption | ||

| Vacuum Consumption | ||

| Limit Switch | ||

| Media at workpiece level | ||

| Clean Room Suitability | ||

Drive Control | ||

| High end |

1) measured with ACS amplifier

2) absolute encoder possible on request

3) without bellows, depending on detail design